Machine embroidery can transform the simplest of fabrics into stunning works of art. Whether you're personalizing a gift or creating branded merchandise, the choice of materials and techniques can significantly affect the final result. One of the most critical, yet often overlooked, elements of successful machine embroidery is the stabilizer. Think of stabilizers as the unsung heroes behind the scenes; they provide the support needed to keep your embroidery looking crisp and clean, prevent distortion, and enhance the overall quality of your work.

Using the right stabilizer for different fabrics is essential to ensure that your designs hold up beautifully during and after stitching. The type of stabilizer you choose can impact how well the stitches adhere to the fabric, how well the design maintains its shape, and how easy it is to remove the stabilizer once your project is complete. In this blog, we’ll explore the various types of stabilizers available, the fabrics they work best with, and how to make the necessary adjustments in your Wilcom design software and sewing machine settings. Ready to dive deeper into the world of stabilizers? Let’s get started!

Stabilizers act as a supportive layer between your fabric and the embroidery stitches. Their primary purpose is to keep the fabric from bunching, stretching, or tearing during the stitching process. When using a machine, the needle, thread, and fabric all need to work in harmony, and stabilizers are essential for achieving this balance.

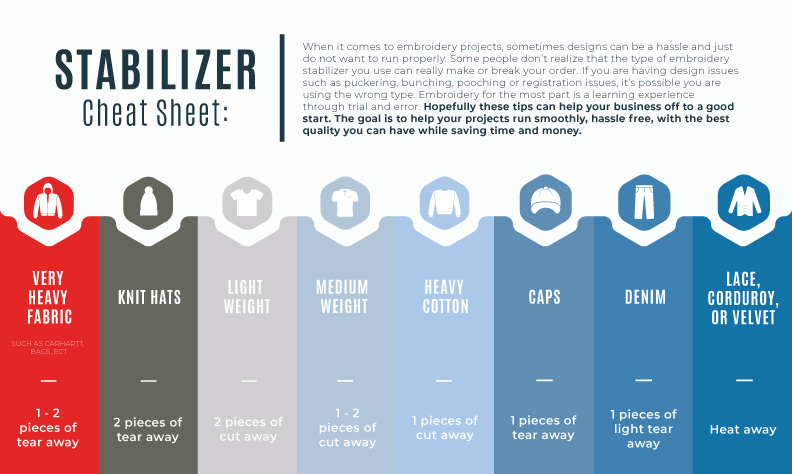

Different stabilizers are designed for various types of fabrics and embroidery techniques. This allows embroiderers to choose the right stabilizer based on the specific project at hand. A well-chosen stabilizer not only leads to a professional finish but also reduces potential frustrations associated with puckering, shifting, or other issues that may arise during the embroidery process.

Types of Stabilizers

Description and when to use: Tear-away stabilizers are sheets that can be easily torn away after the embroidery is completed. They provide a good amount of support without adding bulk, making them ideal for lighter fabrics.

Ideal fabrics: Use tear-away stabilizers for light to medium-weight fabrics such as cotton or polyester. They are particularly useful for embroidery designs that don’t require heavy stitching.

Characteristics and benefits: Cut-away stabilizers provide excellent support and are not easily removed. They prevent distortion and are perfect for designs with a lot of stitching or for fabrics that stretch.

Best applications: Ideal for knits, stretchy fabrics, or products like garments where the fabric might shift. Since cut-away stabilizers remain in place, they provide long-term stability.

How they work and why they are used: Water-soluble stabilizers dissolve in water, leaving no residue behind. They are fantastic for delicate fabrics, intricate designs, or projects where you want the backing to disappear completely after stitching.

Ideal for delicate fabrics: Use water-soluble stabilizers when working with lace, lightweight tulle, or other sheer materials where you want to avoid the appearance of traditional stabilizers.

Fusible Stabilizers

Overview of fusible stabilizers: Fusible stabilizers feature an adhesive backing that can be fused to the fabric using heat. They provide excellent support, especially for fabrics that fray or need extra stability.

Applications: Best for use with leather or fabrics that require heat setting. They add stability during the stitching process and can help keep contours in place.

Stabilizer Selection for Different Fabrics

Cotton

Cotton is one of the most versatile fabrics, and using a stabilizer helps achieve clean, professional-looking designs.

Recommended stabilizers: Tear-away stabilizers work well for cotton, while a cut-away option may be better for denser designs.

Wilcom and machine adjustments: In Wilcom, adjust the stitch density for cotton to create a balanced appearance. Set the machine tension for cotton threads, ensuring they glide smoothly through the fabric without puckering.

Towels

Towels require special consideration due to their absorbency and pile. Characteristics of towels: A heavier cut-away stabilizer is typically recommended here. It allows the stitches to penetrate the fabric while preventing distortion from the plush pile.

Wilcom and machine adjustments for towels: Increase the underlay stitch count in Wilcom to secure the design adequately. On the machine, use a larger needle to avoid getting caught in the fibers.

Leather

Leather is a unique fabric that also requires specific stabilizers for successful embroidery. Suitable stabilizers: Fusible stabilizers work well since they provide the necessary support and prevent fraying.

Specific adjustments in Wilcom and on the embroidery machine: Adjust the needle settings to a leather needle, and set Wilcom to a lower stitch speed to maintain control. Ensure proper tension to prevent the leather from puckering.

Stretch Fabrics

Stretch fabrics can pose challenges, but they also offer fantastic opportunities for creative designs. Need for special stabilizers: Use cut-away stabilizers that absorb stretch and allow the fabric to recover without distortion.

Adjustments in Wilcom and machine settings: In Wilcom, opt for designs with a bit more underlay and looser tension. Set the machine up with a ballpoint needle that can glide over the elastic fibers without causing damage.

Adjustments in Wilcom Design and Machine Settings

Wilcom Design Adjustments

The design software you use is pivotal in achieving optimal results. Adapting settings such as stitch density and underlay options can significantly affect how your finished product looks. For instance, increasing the underlay stitches for fabrics like towels or stretch can ensure better stabilization. Similarly, adjusting the stitch density allows you to customize how closely packed your threads are based on the fabric type. For cotton, aim for a moderate density, while for leather, a less dense stitch may yield better results.

Your embroidery machine settings also require careful consideration. Key elements like tension, speed, and needle choice must align with your fabric and stabilizer combinations. For example, adjusting the thread tension higher for densely stitched designs can improve stitch quality. Additionally, using the correct needle size according to the fabric thickness can prevent issues such as skipped stitches or excessive punching.

Conclusion

Choosing the right stabilizer for your machine embroidery projects is crucial for achieving beautiful, professional results. By understanding the characteristics of various stabilizers and how they interact with different fabrics, you can improve your embroidering skills significantly. Remember to make the necessary adjustments in your Wilcom design software and embroidery machine settings based on the fabric you’re working with. This holistic approach will help you avoid common pitfalls and achieve stunning embroidery outcomes.